Detects and interprets weather changes that impact ice control measures

WM | Weather monitoring

Winter maintenance doesn’t require a standard weather forecast, but rather expertise, collaboration, and sharp decision-making at the right moment. The meteorologists at BG-Engineering don’t operate from a distance — they work alongside the winter maintenance coordinator. For us, quality lies not in more numbers, but in better interpretation and clear explanation, tailored to the region and the coordinator’s decisions.

Prepared for the Future

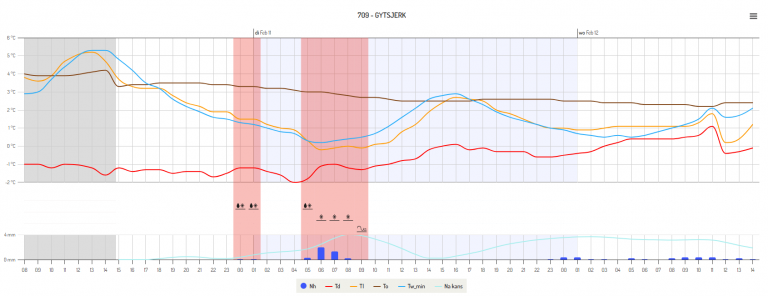

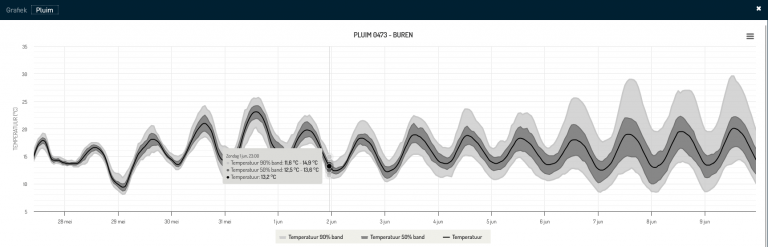

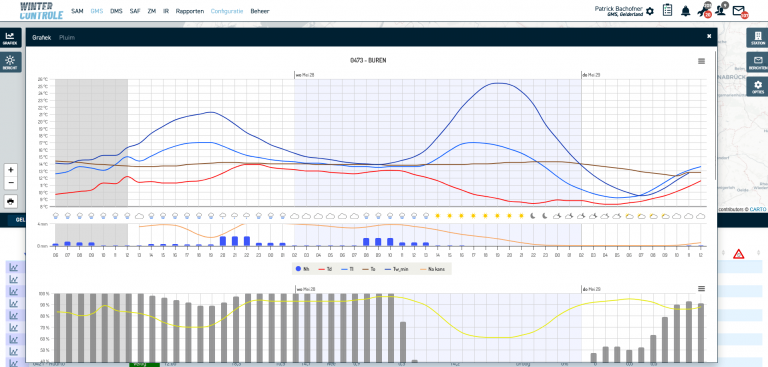

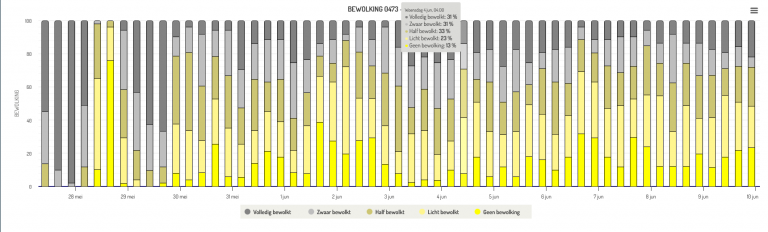

At BG-Engineering, we’ve developed a system that’s ready for the future. All the existing elements remain, but with new features added. We’re currently exploring how weather information can better align with the realities of operational execution. That’s why we use three different weather models and leverage AI to determine which model performs best in each given situation.

We also ask whether regional forecasts are still the most useful, or whether a more detailed level — for example, based on gritting routes — would be more desirable in the future. This includes factoring in precipitation seen on radar but not passing over a measurement point within the management area. This means snow or freezing rain will no longer be missed! We’re also investigating the integration of spreader visibility from the gritting management system as a possible expansion.

Social Gritting and Clear Communication

Through daily video briefings (with replay available in case of icy conditions) — and more frequently in cases of extreme weather (such as heavy snow or freezing rain) — knowledge is consistently shared. These briefings also help establish a clear process that naturally leads to a gritting decision throughout the day.

Our aim is to shift much of the work typically done ad hoc into daytime hours, so the evening operations are as prepared as possible. We call this social gritting. The main goal is to minimize uncertainty and reduce the burden on organizations. Our website prioritizes reliability and clarity: showing only what matters, with smart analytics and clear communication.

Service Specifications

Our winter maintenance services include the following components:

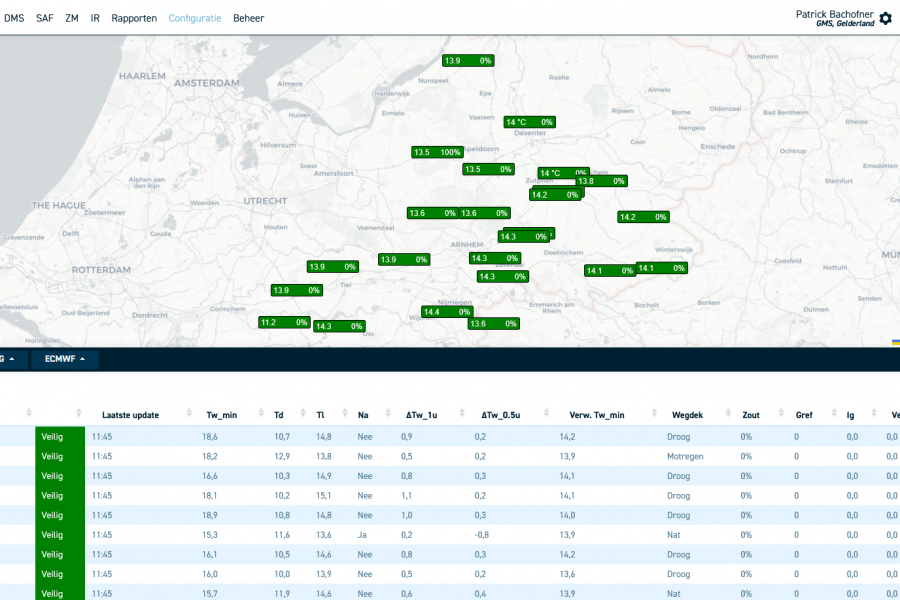

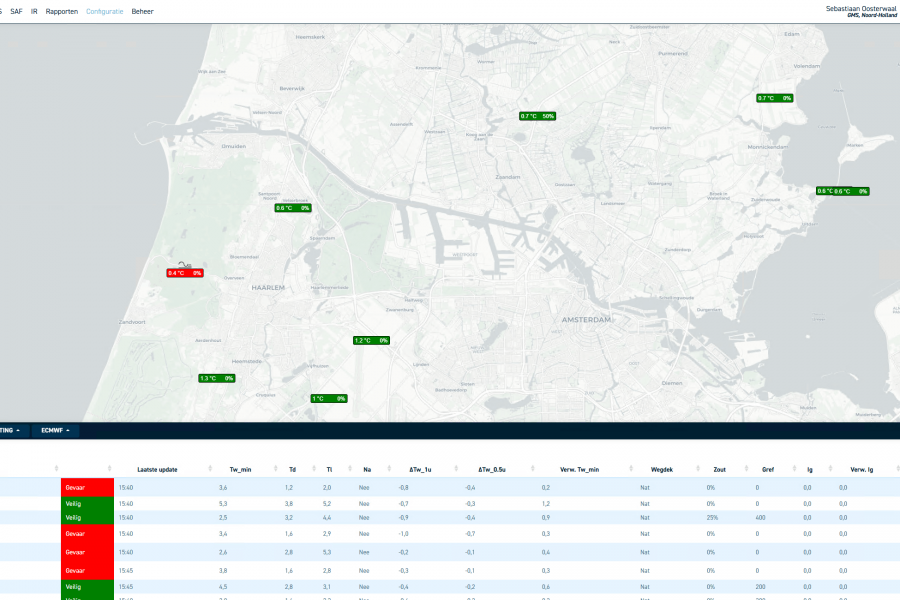

- Real-time weather data via Winter-controle.nl

- Ice forecast delivered by email

- Daily video briefings during icy conditions

- Precipitation radar images

- Weather maps

The email forecast keeps you informed daily about expected weather conditions and possible slipperiness in your management area.

You can also easily inform others about (gritting) actions via the website’s notification center.

Forecasts and Real-Time Information

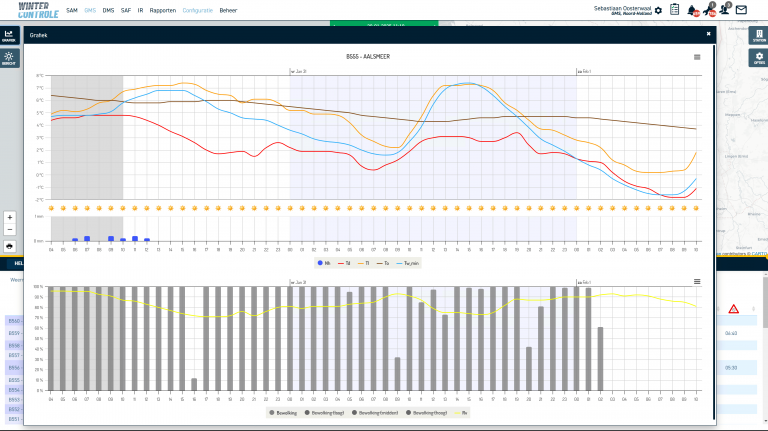

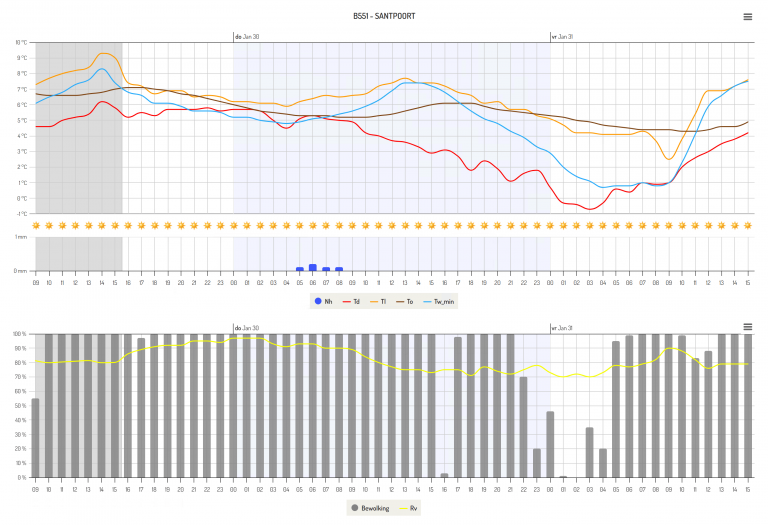

The short-term forecast extends up to 36 hours; the long-term forecast goes up to ten days. The national forecast text (for context) is updated every three hours automatically — or more often if weather conditions require it.

Tables and charts refresh hourly; GMS (Gritting Management System) data refreshes every five minutes.

Each monitoring station includes a plume forecast with automatic interpretation and a traffic light system:

Red means slipperiness, Green means safe. No searching — just instant clarity on what to expect.

Active Interpretation and Smart Alerts

When slipperiness is expected, we proactively contact the winter maintenance coordinator. Alarms, trends, and anomalies from the GMS are interpreted — not simply forwarded.

In addition to regular monitoring, automated checks ensure that nothing is overlooked. Alarm deadlines in the evening or night can be preset, so the meteorologist and/or coordinator receive timely reminders of critical moments — making forgetfulness a thing of the past.

Smart (AI) Analyses for Reliable Interpretation

The system incorporates smart (AI-driven) auto-analyses, including:

Salt status – indicates whether the road surface is salted or not.

Moisture status – ranging from dry, drying, damp, wet, to condensation or hygroscopic conditions.

Conductivity modeling – automatically calculates the freezing point based on current salt and moisture conditions.

These conductivity models consider:

Reduced conductivity in drying conditions

Changes due to condensation, frost formation, or precipitation

The hygroscopic behavior of salt

All these analyses are combined with the current road and weather conditions into clear warnings and actionable interpretations for coordinators.

Not an overload of numbers, but insight and meaning.

Continuous Quality Monitoring and Process Improvement

To ensure reliable information for winter maintenance, we maintain strict process management and continuous quality monitoring.

The entire information chain is regularly evaluated and adjusted where needed.

Field feedback and seasonal evaluations lead to targeted improvement actions.

Processes, tools, and communication are constantly being refined.

Our team remains up to date through training and knowledge sharing, so we can respond flexibly and expertly to changing circumstances.